Platform “MAVERIC"Tray Model for the experimental validation of cooling by controlled injection

The MAVERIC platform offers experimental characterization and modeling of flow turbulence as well as the interpretation of thermal phenomena and fluid mixtures.

Field of applications

- Aeronautics

- Materials

- Liquid and gaseous processes

Themes and skills

- Instrumented test bench for internal aerodynamic studies, physical analysis of

flows, turbulence, etc. - Acoustics

- Validation of calculation programs and turbulence models

- On-site PIV (Particle Image Velocimetry) measurement campaigns if non-opaque fluids can be observed through transparent portholes.

Equipment and Instruments

Test bench for aerodynamic studies

- An air supply device with two centrifugal compressors driven by two threephase motors powered and controlled by two regulators (Siemens 420). A mass flow meter (CNRS Pprime patented) is installed on one of the two pipes.

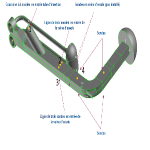

- Two superimposed rectangular metal channels, 2.5 cm long and 0.4 m x 0.12 m in cross-section, which allow two incident flows to be established. The system is calibrated for an operating range between 0 and 500 Pa with an accuracy of approximately 1Pa. The upper channel is connected to a sound box equipped with a 300 mm diameter Raptor loudspeaker.

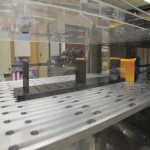

- The 0.8 x 0.4 x 0.12 m3 Plexiglas test model can accommodate a central plate bearing a given perforation pattern (single hole, row of holes or multiperforation).

Punctual speed measurement: a Dantec/TSI laser Doppler velocimeter (a 4W argon continuous laser with its external cooling system, a colour separator with four colours for optical fibre, an optical fibre equipped with a transmission and reception head (Dantec), a signal analyser coupled to acquisition software (TSI)

Planar velocity measurement: a LaVision two- or three-component planar particle imaging velocimetry system; 2 pulsed Yag lasers (Quantel), 2 ProX CCD cameras (LaVision), an optical arm and two slick generators, a synchronization unit and processing software (LaVision)

Liquid spray seeding system (LaVision)

A set of four microphones (Bruel and Kjoer) with their conditioner and an acquisition system (National Instrument) driven by LabView.